ANSI VALVES

General Overview ANSI Valves

Australian Pipeline Valve (APV) is a modern dynamic organisation

specialising in the design, development, manufacture and marketing

of top quality valves for a range of industries. APV is firmly committed

to technological developments and will continue striving to provide

a quality product at a competitive price to meet the needs and

requirements of our customers in a timely manner.

APV’s excellent record of quality products and outstanding

service is based on a desire to meet global demand

and standards for the valve industry in the 21st century.

As a valve specialist, APV’s product range includes Ball, Gate, Globe, Plug and Check valves in cast and forged. Our valves are manufactured for a broad range of applications which includes the oil and gas industry, chemical and petrochemical, mining, and power generation

APV’s entire product range is manufactured with the use of high quality materials and advanced manufacturing technology which ensures the highest possible product quality. All valves are manufactured to ASME/API standards. Our growth

is testament to our commitment to product quality

and our customers.

APV Valve Manufacturing Range Overview

Superseal Butterfly Valve Overview

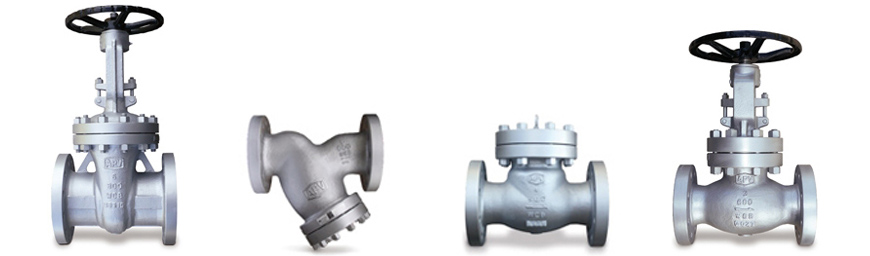

GATE VALVES

Gate valves are primarily used as stop valves being

either fully opened or fully closed. Gate valves are characterised by

a travelling wedge that travels perpendicular to the direction of the flow. Gate valves usually have a minimum pressure drop when fully opened, provide tight shut-off when fully closed and remain relatively free of contamination build-up.

Cast Steel Gate Valves

Construction: Outside screw and yoke, bolted/welded or pressure seal bonnet, non rising handwheel or gear operated, flexible or solid wedge.

| Design: | API 600, ANSI B16.34, API603 |

| Face to Face: | ANSI B16.10 |

| End Types: | Flanged ANSI B16.5 or Butt weld to ANSI B16.25 |

| Pressure/Temperature: | ANSI B16.34 |

| Rating: | Class 150, 300, 600, 900, 1500 & 2500 |

| Sizes: | Up to 1300NB (52") |

Forged Steel Gate Valves

Construction: Bolted, pressure seal or welded bonnet, regular bore or full bore, outside screw and yoke, available in threaded, socket weld and flanged ends.

| Design: | API 602, ASME B16.34. |

| End to End: | ANSI B16.10. |

| Ends NPT/SW: | ANSI B16.11/B16.1. |

| Ends Flanged/BW: | ANSI B16.5/B16.25. |

| Rating: | Class 150, 300, 600, 800, 1500, 2500, 2690 & 4500. |

| Sizes: | Up to 100NB (4"). |

GLOBE VALVES

Globe valves are primarily used as control valves where moderate control or regulation of flow is required. Globe valves are marked with flow direction arrows as they are recommended to be installed with flow and pressure under the disc. The amount of force to close a globe valve against pressure is much higher than gate valves but the stem travel distance is much shorter.

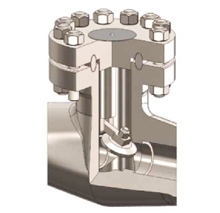

Cast Globe Valves

Construction: Outside screw and yoke, bolted, welded or pressure seal bonnet, rising stem, rising handwheel, swivel plug or ball type disc.

| Design: | API 623, BS1873, ANSI B16.34 |

| Face to Face: | ANSI B16.10. |

| Ends: | Flanged to ANSI B16.10, Butt weld to ANSI B16.25. |

| Rating: | Class 150, 300, 600, 900, 1500 & 2500. |

| Sizes: | Up to 900NB (36”). |

Forged Steel Globe Valves

Construction:Bolted, welded or pressure seal bonnet, regular or full bore, outside screw and yoke, available in threaded, socket weld and flanged ends.

| Design: | API 602, ASME B16.34, BS5352. |

| End to End: | ANSI B16.10. |

| Ends NPT/SW: | ANSI B16.11/B16.1. |

| Ends Flanged/BW: | ANSI B16.5/B16.25. |

| Rating: | Class 150, 300, 600, 800, 1500, 2500 & 2690. |

| Sizes: | Up to 100NB (4”). |

CHECK VALVES

Check valves are single direction flow valves used to allow unlimited flow in one direction and to restrain flow in the opposite direction. Check valves are normally designed for installation in horizontal lines but may also be used in vertical lines where the flow is upward under the disc.

Swing Check Valves

Swing check valves are straight through flow valves which work automatically. The disc swings from the seat upon exertion of fluid pressure on the upstream side. When the direction flow reverses, the reversal pressure and the weight of the disc close the disc against the seat, stopping backflow. This design allows the valves to remain closed even with no flow going through the valves.

Cast Steel Check Valves

Construction:Cast steel swing and piston check valve, bolted, welded or pressure seal cover suitable for horizontal or vertical lines.

| Design: | API 6D, API 594, BS1868, ANSI B16.34. |

| Face to Face: | ANSI B16.10. |

| Ends: | Flanged to ANSI B16.5, Buttweld to ANSI B16.25. |

| Rating: | Class 150, 300, 600, 900, 1500 & 2500. |

| Sizes: | Up to 900NB (36”). |

Forged Steel Check Valves

Construction:Bolted, welded & pressure seal bonnet, regular or full bore, outside screw and yoke, available in piston or swing style, end connections available in threaded, socket weld and flanged ends.

| Design: | API 602, ASME B16.34, BS5352. |

| Ends NPT/SW: | ANSI B16.11/B16.1. |

| Ends Flanged/BW: | ANSI B16.5/B16.25. |

| SW/THD Type: | ANSI B16.11. |

| Flange Type: | ANSI B16.5. |

| Rating: | Class 150, 300, 600, 800, 1500, 2500 & 2690. |

| Size: | Up to 100NB (4”). |

Wafer Check Valves

Wafer check valves are available in single and dual plate. The design is lighter and more compact than a swing check valve, making it easier to install and lower in cost. Retainerless & retainer style available.

| Construction: | Cast or forged one piece body, independent plates. |

| Design: | API 594. |

| Face to Face: | ANSI B16.10, API594 |

| Ends: | ANSI B16.5. |

| Rating: | Class 150, 300, 600, 900, 1500 & 2500. |

| Sizes: | 25NB (1”) to 900NB (36"). |

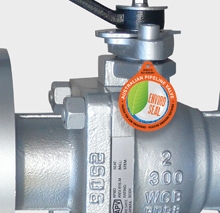

BALL VALVES

Ball valves can be used to handle a variety of liquids, suspended solids and gases. Ball valves are suited for fluid flow requiring assured performance, tight shut off, constant torque and no maintenance.

Ball Valves Technical Information

Floating Ball Valves

Floating ball valves offer quick, quarter-turn operation, visual indication of the valve position, straight uninterrupted flow and compact size. The full bore design minimises pressure drop across the valve while maximising flow capability and throughput economy for general in line services.

Construction:1 or 2 piece split body, full or reduced bore, free floating ball, combination lock stop, antistatic design, blowout proof stem, cavity relieving seats.

| Design: | API 6D, API 608. |

| Face to Face: | ANSI B16.10. |

| Ends: | Flanged to ANSI B16.5, Buttweld to ANSI B16.25. |

| Rating: | Class 150, 300, 600. |

| Sizes: | Up to 250NB (10”). |

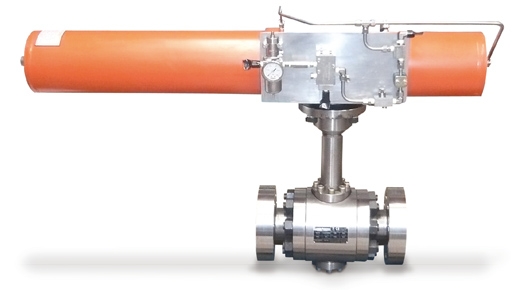

Trunnion Mounted Ball Valves 2 Piece Cast

Trunnion mounted ball valves have been designed for severe oil and gas applications, including production, transportation and distribution.

Construction:2 piece split body, full bore, trunnion mounted ball, independent ball and stem, antistatic design, cavity relieving seats, double block and bleed.

| Design: | API 6D. |

| Face to Face: | ANSI B16.10. |

| Ends: | Flanged to ANSI B16.5, Buttweld to ANSI B16.25. |

| Rating: | Class 150, 300, 600, 900, 1500 & 2500. |

| Sizes: | Up to 750NB (36”). |

Trunnion Mounted Ball Valves 3 Piece Forged

Trunnion forged steel ball valves are suitable to withstand the harsh service conditions often present in the petroleum industry. These valves are recommended for tight shut-off in high pressure and arduous fluid applications.

Construction:3 piece forged steel split body, full bore, trunnion mounted ball, independent ball and stem, antistatic design, cavity relieving seats, double block and bleed. Double piston effect (DPE) seats on request.

| Design: | API 6D. |

| Face to Face: | ANSI B16.10. |

| Ends: | Flanged to ANSI B16.5, Buttweld to ANSI B16.25. |

| Rating: | Class 150, 300, 600, 900, 1500 & 2500. |

| Size: | Up to 1000NB (40”). |

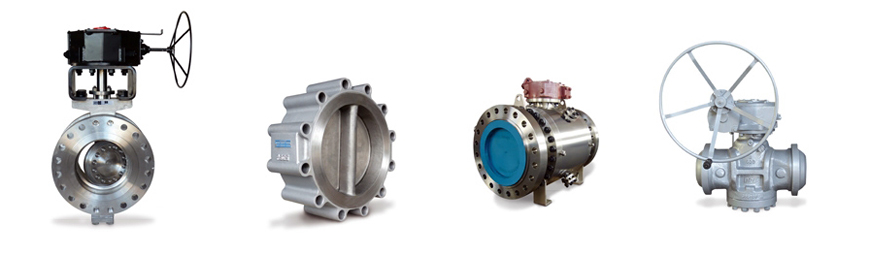

BUTTERFLY VALVES

Butterfly valves can be used to handle a variety of liquids, suspended solids and gases. Butterfly valves are suited for fluid flow requiring assured performance, tight shut-off, constant torque and no maintenance. Styles available include high performance, lined, and O-ring seal. High performance butterfly valves are available in concentric, double eccentric and triple eccentric (offset) styles.

Construction:Cast or forged body in wafer, flanged and lugged connections.

| Design: | API609, BS5155 |

| Face to Face: | ANSI B16.10 |

| Ends: | ANSI B16.5 |

| Rating: | Class 150, 300, 600, 900 & 1500 |

| Size: | Up to 1400NB (56”) |

PLUG VALVES

Lubricated quarter turn plug valves are suitable for service in the petroleum industry but also for slurry use in full port configuration. For severe applications including production, transportation and distribution.

Construction:Bolted bonnet, full bore and regular port, lubricated metal to metal seating, inverted tapered plug, dynamic pressure balance, regular pattern and venturi pattern, antistatic design, firesafe.

| Design: | API 6D, API599 |

| Face to Face: | ANSI B16.10. |

| Ends: | Flanged to ANSI B16.5, Buttweld to ANSI B16.25. |

| Rating: | Class 150, 300, 600, 900, 1500 & 2500. |

| Size: | Up to 900NB (36”). |

PRODUCT RANGE SUMMARY

Ball Valves

CF8, CF8M, WCB, 316, F51, LF2, A105, A20, Bronze.

Split body ball valves up to 2500 class in floating and trunnion mount. Flanged, screwed and weld end. Also stocking metal seated, PEEK, Graphite and CPTFE seated.

Butterfly Valves

High performance - metal and resilient seat, firesafe as well as rubber and PTFE lined.

Plug Valves

To 2500 class, firesafe certified, lubricated and lined.

Dual & Single Flap Wafer Check Valves

Iron, Steel and S/S up to 750NB, 150 to 2500 class and API3/5000.

Cast Gate, Globe & Check Valves

Up to 2500 class, WCB, WC6, WC9, WCC, LCC, LCB, CD3MN, CF8M, CF8, C5, F51, Bronze, Monel, A20.

Forged Gate, Globe & Check Valves

To 2690 class in F22, F11, F5, F51, A20, A105, LF2, 316L, 316, 304.

Steam Valves

Stop Check (SDNR), Right Angle Globe, Parallel Slide and Geo-thermal Gate Valves.

Actuation & Controls

Fully equipped automation facility. Pneumatic actuators up to 30,000Nm.

Pipeline Products

• Strainers

• Sight Glasses

ANSI VALVE MANUFACTURING RANGE

APV specialises in ANSI (ASME) Valves manufactured in the following range of types, sizes and pressure class ratings:

ANSI Valve Manufacturing Range

APV - CAST STEEL VALVES

| Gates | 2” - 48” | 150# - 2500# |

| Globes | 2” - 24” | 150# - 2500# |

| Swing Checks | 2” - 36” | 150# - 2500# |

| Tilt Disc Checks | 2” - 12” | 150# - 300# |

| Stop Checks | 2” - 24” | 150# - 2500# |

APV - FORGED STEEL VALVES

| Gates | 1/2” - 3” | 150# - 4500# |

| Globes | 1/2” - 2” | 150# - 2500# |

| Checks | 1/2” - 2” | 150# - 2500# |

APV - PRESSURE SEAL VALVES

| Gates | 2” - 60” | 600# - 4500# |

| Globes | 2” - 24” | 600# - 4500# |

| Y-Pattern Globes | 2” - 36” | 600# - 4500# |

| Swing Checks | 2” - 24” | 600# - 4500# |

| Tilt Disc Checks | 2” - 12” | 600# - 4500# |

APV - BALL VALVES

| Floating Balls | 2” -18” | 150# - 600# |

| Trunnion Balls | 2” - 36” | 150# - 2500# |

APV - PLUG VALVES

| Lubricated | 2” -30” | 150# - 2500# |

| Non-Lubricated | 2” - 24” | 150# - 600# |

APV - BUTTERFLY VALVES

| Double & Triple Offset | 2” -120” | 150# - 1500# |

ANSI/ASME RELATED LINKS

APV Valve Production Program

APV Valve Technical References

APV Ball Valve Technical References

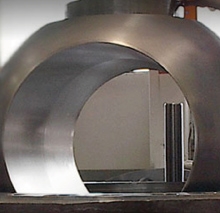

APV Pressure Seal Bonnet Overview

APV API600 Trim Chart

APV ASME B16.34 Valve Selection & Design Criteria

APV Valve Performance Features

APV Superseal Valves