STEAMCO

OVERVIEW

Steamco manufactures cast steel steam valves for boilers, geothermal applications, power plants and general steam applications. Valves are manufactured in ASME class 150, 300, 600, 900, 1500 as well as AS and BS table D to H and PN 2.5 to 420.

Valves Manufactured

Isolation valves: Parallel Slide Gate Valves and Geothermal Gate Valves. Piston Valves, Bellows Sealed Valves, Continuous Blow Down Valves.

Stop/check valves: Piston Check Valves, Stop Check Valves (Screw Down Non Return) in inline, right angle and inclined patterns as well as Blow-Off Globe Valves in straight way, ‘Y’ (wye) type and right angle style.

All valves have CA15/410 stainless steel trim (CR13) with stellite overlay seat. Special trims are available in short delivery times. Sizes available range from 15mm (1/2”) NB to 500 (20”). Hammer blow hand wheels, gear operators and chain wheel operators are available where required. Undrilled valves are kept ex-stock in many sizes to accommodate any drilling such as BS, AS, DIN, and JIS. Buttweld ends are also available. All types of Steamco valves can be supplied in quick delivery.

In many cases valves utilised as Blow-Off valves by the steam industry are manufactured under the Australian Pipeline Valve (APV) name as they form part of the broader APV range, (e.g. Y-type forged globe valves, conventional cast globe valves, pressure seal bonnet, high pressure power station valves). Consequently also refer to our APV brand range of Gate, Globe and Check valves.

|

Bellows Sealed Globe Valve |

Rack & Pinnion Blow Down Valve |

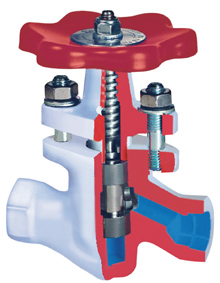

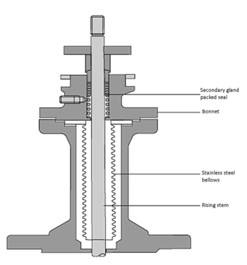

BELLOWS SEALED VALVES

In APV-Steamco bellows sealed valves, a flexible metallic bellow is used as the primary stem seal to prevent leakage. It is connected on one end to the stem and the other end is connected to the bonnet, effectively producing a barrier between the fluid and the environment. This bellow expands and contracts as the stem moves up and down. The bellows, in conjunction with the secondary gland packing, is so effective it produces a zero emissions seal, meaning bellows sealed valves are an inherently fugitive emission design. Fitted to the bellows is an anti-torsion device, which prevents the bellows from rotating with the stem.

Although less costly than the bellows sealed valves, the traditional gland packed valve does not produce the same level stem seal as the bellows design. If a gland packed valve is not used for a significant period, the gland packing can stiffen, and leakage will occur the next time the valve is used. The bellows sealed valve does not suffer from this problem. Furthermore, gland packed valves require repacking of the gland, whereas a typical bellows requires no maintenance for over 10,000 cycles.

Bellow Design

The most popular stainless steel bellow material is 321 SS. Alternatively, AISI 316Ti, Inconel 600 or Inconel 625 have improved temperature and/or fatigue strength and corrosion

resistance as compared with traditional stainless steel bellows. Similarly, Hastalloy C-276

offers greater corrosion resistance and fatigue strength than

Inconel 625. The size, pressure, valve design, temperature

and service media need to be considered when specifying

bellows material. Fatigue resistance can be improved by

using a multiple bellows system and reducing the stroke

length. This can significantly increase the bellow service life.

APV-Steamco bellows sealed valves are available in gate and

globe designs. These valves are available from 6mm NB to

650mm NB, in pressure rating from ANSI 150 to 2500 class

and PN 2.5 to 420. Material options include carbon steel,

stainless steel and exotic alloys.

Applications

Applications include: steam, hot oil, chlorine, inflammable

chemicals/gas. This valve design prevents product loss and improves plant safety.

Steam Pressure/Temperature Table

GEOTHERMAL/GEYSER GATE VALVES

Steamco also supplies valves for geothermal service. Conventional wedge gate valves in 150 to 600 class in conventional and full port can be supplied in geothermal/geyser trim, 17-4 ph SS stem, stellite overlay seat, disc and back seating. API6D type slab or parallel slide gates can also be supplied for more extreme geothermal service in all pressure classes.

Sample Geothermal Trim Geyser Gate Valve Drawings

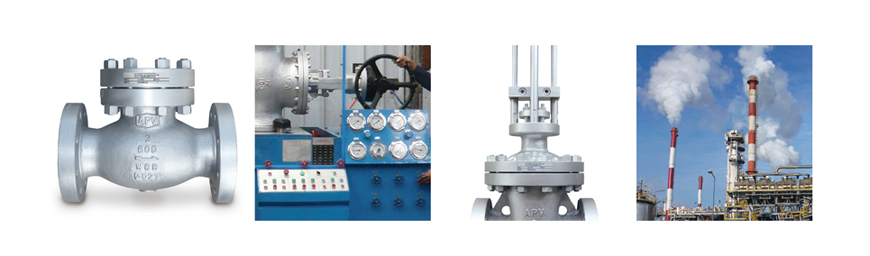

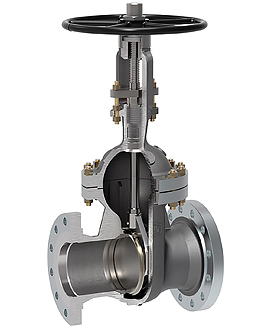

PARALLEL SLIDE GATE VALVES

Steamco manufacture cast and forged parallel slide gate valves in 15NB (1/2”) to 1050NB (42”) from 150 to 4500 class in flanged, screwed and weld ends. Valves are manufactured in pressure seal, bolted and welded bonnet design in forged and cast. In bolted bonnet, the traditional API600 bonnet configuration is produced as well as the pillar and bridge design bonnet. Valves are manufactured in all material grades including WCB, WC5, WC6, WC9, F11, F22, and A105.

Cast Parallel Slide Gate Valve

• From 50NB to 1050NB (2" to 42")

• ANSI 150LB - 2500LB

• Bolted Pressure Seal Bonnet

• Butt Weld, Flanged

Forged Parallel Slide Gate Valve

• From 15NB to 400NB (1/2" to 16")

• ANSI 150LB - 4500LB

• Bolted, Welded, Pressure Seal Bonnet

• Socket Weld, Butt Weld, Flanged

Basic design is available to API600, ASME B16.34, BS 5157, and API6D. End connections available include ASME B16.5 150 to 2500 class, AS 2129 Table D to H, AS 4087 PN14 to 35, BS 4504 PN6 to PN420, EN 1092-1, ISO 7005-1, AS4331-1, PN2.5 to 480.

Sample Steamco Drawings

GLOBE VALVES & PISTON CHECK VALVES

Globe Valves – Stop Check

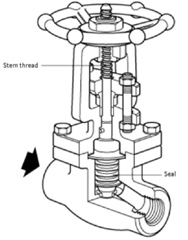

Conventional cast steel plug disc globe valves are also manufactured in ASME class 150 to 2500 as well as AS and BS table D to H and PN2.5 to 420. Steamco globe valves are available in right angle and inline configurations. Y style angle bonnet design is also available. For steam applications globe valves are typically supplied as “Screw Down Non Return” (stop check) providing the benefits of a stop valve and a piston check in the one valve.

Steamco Installation and Operations Manual

Piston Check

Piston check valves are also available for horizontal lines in the same size range as globe valves. They can be supplied c/w a 316 SS or inconel spring for vertical service.

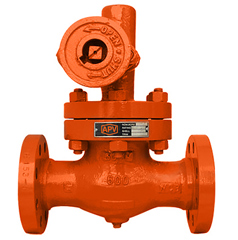

PISTON VALVES

Throughout the world, piston valves are used to regulate and control steam as well as highly aggressive media in the chemical industry as well as for fine regulating in the oil industry. Piston valves are leak tight on the seat as well as through the body to the atmosphere. Consequently piston valves are energy saving and economic. Another major advantage of the piston valve is the ability to replace the valve rings without removing the valve from the line. Due to the design of the piston valve, there is no erosion to the seating surface. Combine this with their ease of inline servicing and the piston valve provides a low maintenance valve.

Various seat designs are available but the conventional piston valve design has stainless and graphite seat seals which combines a hard wearing metal seat with a resilient graphite insert that provides a leak tight shut off and allows a wide temperature range whilst at the same time providing an inherently fire safe. Unlike traditional globe valves, which are a stop and throttling valve, Steamco piston valves are a true isolation valve whilst still allowing a degree of flow regulation. The Piston valve has a superior system to a conventional globe valve, it has a cylindrical piston and two resilient, replaceable jointing rings.

Advantages of Piston valves:

• Exceptional leak tightness across the ports and to atmosphere

• Insensitive to impurities due to the combination sealing system

• Maintenance free

• Unaffected by wire drawing in steam service

• Environmentally safe and energy efficient

• Inherently fugitive emission design

• Valve rings are replaceable in the line

• Excellent control statistics

• Inherently fire safe design

• High return on investment across full service life compared to globe valves

Piston valves are used for the tight shut-off of low and medium pressure steam as well as meeting the service demands of a large number of requirements in fluid handling applications in the industrial sector. They are used in process lines containing many different fluids such as steam, superheated water, thermal transfer fluids, ammonia, LPG, hydrocarbons, acids, alkaloids, etc. Their ability to provide perfect seat shut off and packing tightness, and their long term trouble-free operation, ensured by our reinforced seal rings, have served to greatly expand the number and types of applications where Steamco piston valves are used including their use in the handling of harmful and flammable fluids where a tight seal and packing shut off is essential.

Piston valves are usually T-pattern, straight through flow globe valves, with their stem perpendicular to the process line. Piston valves are typically shut-off valves but by replacing the standard lantern bushing with a characterised regulating lantern bushing, the valves can be turned into control valves to provide a charaterised flow pattern, having manual or automatic service. Since the piston is always held by the upper valve seal ring, no vibration can occur.

Automated Piston Valves

All Steamco piston valves can be used for automatic or remote control service using electric pneumatic or hydraulic actuators.

Piston valves can be easily outfitted with "on-off," "inching" and "modulating" type electric actuators, including tight-seal or explosion proof enclosures. These actuators are usually equipped with a hand wheel for emergency manual operation as well as with control and remote warning unit.

Single or double acting pneumatic or hydraulic actuators can be installed on piston valves: single-acting actuators are of two types: "fail-closed" or "fail-open."

Cast Iron, Carbon Steel, Alloy Steel, Stainless Steel Piston Valves

• ASME Class 125, 150, 300, 800 – DIN 2401 – PN 16/40/63 – API602

• Size 6NB to 200NB (¼" to 8")

• Standard female screwed ends as per: - B.S.P. (DIN 2999) – NPT – ASME B1.20.1

• Socket weld ends – SW to: - ASME B16.11

• Butt weld ends to: - ASME B16.25 and pipe Sch 160, or DIN 3239

• Flanged ends to:

- ASME B16.5

- BS4504

- AS2129

- AS4087

- AS4331 (ISO 7005-1)

- EN 2401/1092-1

Modulating Flow Control Piston Valves

Although piston valves are primarily used as on/off valves, they are also suitable for use as modulating control valves. The flow path for Steamco piston valves provides an excellent means of flow control even when just the standard lantern bushing component is used, even though it is not necessarily designed for modulating flow control. However, a custom modulating flow control piston valve design is available fitted with a lantern bushing that has a multiple hole design and which will yield an equal percentage flow characteristic.

Upon request, linear or quick opening flow characteristics are also available.