HYDROGEN VALVES

Australian Hydrogen Valve manufacturer. Fast track, short lead time.

Click here for urgent, fast track supply or ex stock of Hydrogen Valves.

APV Flowturn & Twinlok valves & fittings for hydrogen systems are designed to deliver the high level of safety, reliability and high performance for on-vehicle and infrastructure applications.

Australian Pipeline Valve manufactures valves for hydrogen including ball valves, check valves, plug valves, needle valves, relief valves, safety valves as well as actuators & tube compression fittings. To ensure the high level of quality and safety for hydrogen systems, APV has applied a higher standard in designing, manufacturing and testing. The higher standard covers the raw material specification, brands of resilient sealing parts, tolerance and surface roughness of machined parts, inspection and testing specification, and where applicable EC79, ANSI HGV, UN/ECE-R134 certification.

What Makes Hydrogen Valves Different?

Hydrogen molecules are extremely small, hence providing a leak free valve requires a special design. Any escaping gas can pose a safety risk and is also wasteful. As hydrogen molecules are so small, they can in fact diffuse into lower-quality stainless steels. This phenomenon is known as hydrogen embrittlement. Over time, pressure can produce fissures in the material, which can become highly problematic in hydrogen service.

Technical Considerations Hydrogen Valves & Fittings

Hydrogen Compatible Raw Materials:

- Modified 316/316L stainless steel with higher Ni, CR and Mo content. The Ni is not less than 28.5% which provides better resistance to hydrogen embrittlement.

- Low-temperature FKM or EPDM o-ring for harsh working conditions.

- XM-19 material applied for valve stems to provide higher strength and hydrogen embrittlement resistance.

Dimensions and tolerances as well as hardness variation of the fittings and valves for hydrogen applications becomes more critical.

Stringent Test Standards Guarantee Safety and Reliability.

All products for hydrogen applications are typically tested with stricter leakage standards than EC79 and HGV 3.1.

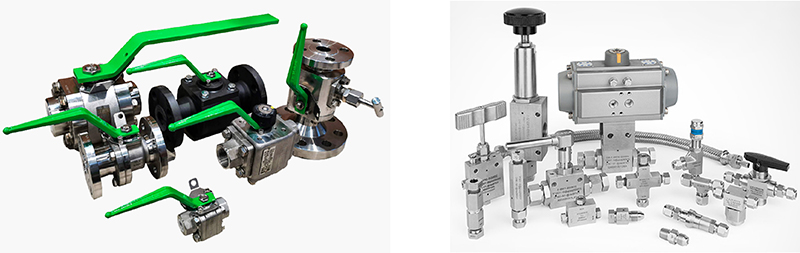

APV Hydrogen Ball Valves

APV manufactures 2 way & 3 way hydrogen ball valves. When selecting ball valves for hydrogen applications, the stem seal design is critical & must be highly resistant to wear. APV manufacture a trunnion mounted ball valve with a direct-load design, which helps to enable leak-tight performance with every activation and shutoff. A bottom-loaded stem design can also reduce any potential stem blowout, offering enhanced safety.

APV Hydrogen Needle Valves

APV needle valves are used to make fine adjustments in the amount of fluid flow. Needle valves are typically all-metal in construction, requiring a large amount of force to seal properly. Such a force has the potential to deform the needs itself and possibly the seat, creating a potential hazard and requiring costly maintenance. Hence APV manufactures a heavy duty design for hydrogen service that can resist deformation during repeated use. Only APV needle valves are properly pressure-rated and capable for common hydrogen applications (350/700 bar).

APV Hydrogen Check Valves

APV check valves perform essential safety functions in hydrogen compressors in refuleing systems, controlling excess backflow. Most check valves incorporate springs - components that are typically made with strain hardened material that can be more susceptible to hydrogen embrittlement than high - quality 316 stainless steel. Additionally, vehicle fuelling applications subject such valves to large, fast changes in temperature and pressure, creating elevated stress on the valves elastomer seals. Ball check valves are a more suitable option for hydrogen compressors. APV ensures material integrity and compatibility with our hydrogen components.

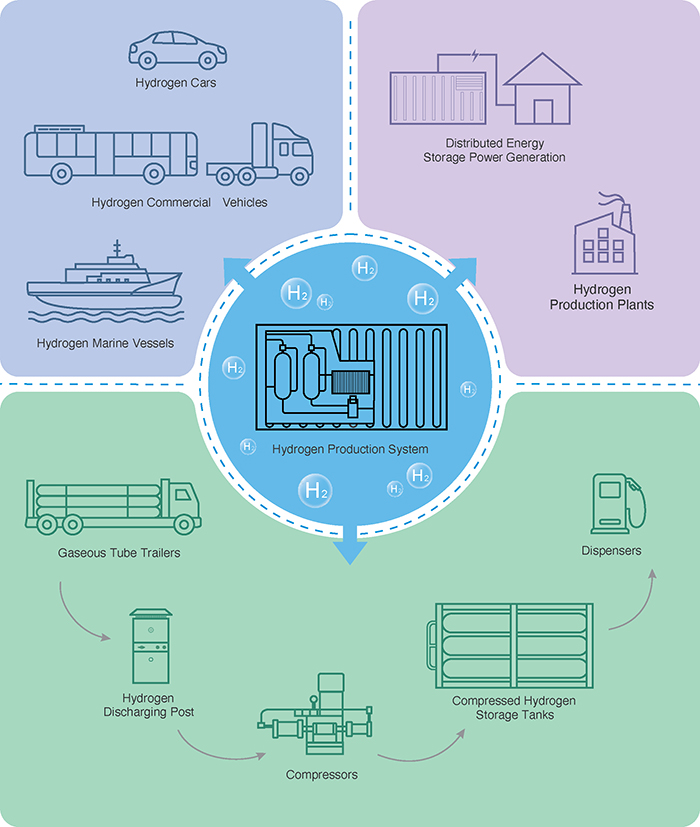

Typical Hydrogen Applications

Click here for Geothermal Ball & Gate Valves.