Fugitive Emission Certified Valves in stock ISO 15848, API 622/624

April 2, 2025

Production plants generate gas emissions known as volatile organic compounds (VOCs) and hazardous air pollutants (HAPs).

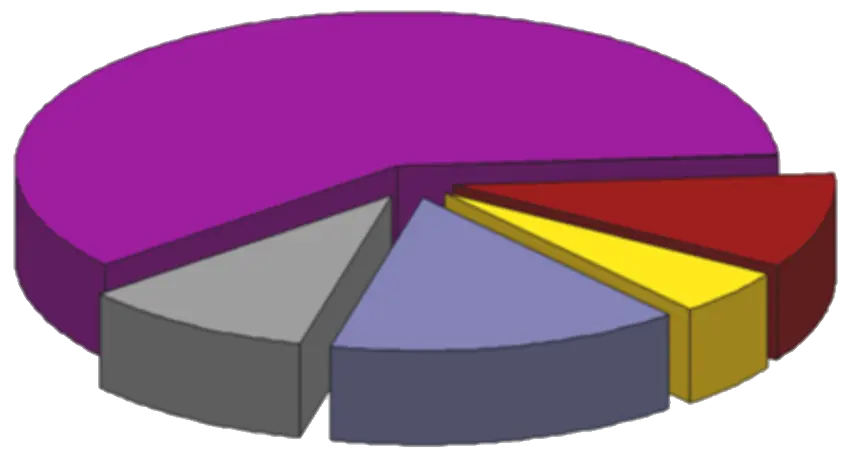

60% of all fugitive emission piping systems come from valve stem packing.

These gases enter our atmosphere, contributing to ozone, smog, and other organic aerosols forming. At the same time, these pollutants can hurt the environment and even cause severe health complications for humans. A flood of low-cost country (LCC) valves was installed throughout Australia during the construction boom (driven by lowest-cost tender systems), with poor quality machining tolerances and poor quality gland packing. Generic brand gland packing fitted to LCC valves will dry out, shrink, crack, and absorb water, and subsequent corrosion will increase gland area leakage, especially gases.

There is a worldwide drive to reduce methane, H20, and CO2 emissions substantially and graduate to a greener and cleaner environment. Australia has set itself an ambitious target of transitioning to net-zero emission by 2030, assisted by implementing various strategies such as electric vehicles and solar, hydro and wind farms.

Fugitive emissions from valves and piping systems are centre stage when it comes to the race to net zero, and, as such, a majority of new pipeline projects are now demanding fugitive-emission-certified valves.

Independent tests have shown methane gas leakage at some on-shore oil & gas facilities. Refineries and factories in Australia must observe fugitive emission requirements. Methane is 84 times more potent than CO2 over the first 20 years. Most companies are now proposing a move to target zero emissions by 2030 or 2040.

Fugitive Emission Valves Available

All new shipments of APV and Bonney Forge valves will be fugitive emission packed as standard. Of course, our existing stocks of JC, Sferova, Starline & APV triple barrier stem seal trunnion mounted ball valves fully conform to ISO 15848 fugitive emission standard requirements.

DNV Witnessed Fugitive Emission Prototype Certified APV Valves:

- Forged and cast gate valves

- Forged and cast globe valves

- High performance double & triple offset butterfly valves

- Lubricated plug valves

- Floating ball valves in forged and cast, screwed and flanged

- Trunnions mounted ball valves

We keep large stocks of APV valves - see our complete stock list here. Click here for details on certification.

Our valves work to reduce and even prevent harmful emissions released into the environment by oil, gas, chemical and toxic plant operations. They also increase plant efficiency and pass periodic leak detection for emissions monitoring over the valve's entire lifecycle.

For gland-packed valves in stock, we specify Chesterton 1622 Inconel wire reinforced die-formed fugitive emission packing, Garlock EVSP 9000 packing sets, or Burgmann 6070 Inconel wire reinforced die-formed packing. In addition to ensuring gland-packed valves are fugitive emission compliant, these advanced gland packings also have other advantages. They will not shrink or absorb moisture and are low friction. In addition, they are impregnated with high-temperature blocking agents, lubricants and a passive corrosion inhibitor to prevent galvanic corrosion of valve parts in contact with the packing and prevent stem and stuffing box pitting, unlike active inhibitors such as zinc; passive inhibitors are not consumed.

Of course, the stem smoothness and stuffing box smoothness of APV and all other brands stocked are specified by GSL to ensure conformance with the fugitive emission service.

In addition, the above-mentioned fugitive emission packing brands are also fire-safe tested to API 607/589. The above-mentioned gland packing also has independent fugitive emission certification to ISO 1548-1 & API 622. Consequently, not only are all the valves that GSL stock in JC, Sferova, Starline & APV Fugitive emission prototype certified, but in the case of the gland-packed valves - the packing itself is also fugitive emission certified, and the valve tolerances are specified for fugitive emission service.

Actual fugitive emission testing can be performed on each valve where required.

Fugitive emission and quality packing are also a safety issue for employees as well as a fire risk.

60% of emissions, including volatile organic compounds & CO2, can be sourced from valves within a pump system (just as an example), with relief valves, tanks, pumps and flanges individually making up only small percentages of overall emissions released into the air.

Australian Pipeline Valve has a full range of fugitive emission certifications. Please visit Global Supply Line or Australian Pipeline Valve websites for APV, JC, Sferova & Starline fugitive emission certifications.

Standards and Testing:

- ISO 15848-1: This standard is used for fugitive emission certification of valves.

- API 622: This standard tests process valve packing for levels of fugitive emissions.

- API 624: This standard tests rising stem valves equipped with graphite packing for any fugitive emissions.

- API 641: This standard is used for testing of gland packing qualified to be used on APV gland packed valves.

- ISO 15848-2: Special batch testing can be performed as required.

- Fugitive Emission Testing: Helium is used as a testing medium to measure the overall leak rate from the stem seal using a helium mass spectrometer.

ISO 15848-1. This testing procedure evaluates external leakage of valve stem seals (or shafts) and body joints of isolating valves and control valves. It involves pumping helium or methane through the valve and measuring any escaping gas digitally. Because it applies to seals and joints, it is seen as a "whole valve" test. It provides acceptable measurement, test, and qualification procedures for fugitive emissions.

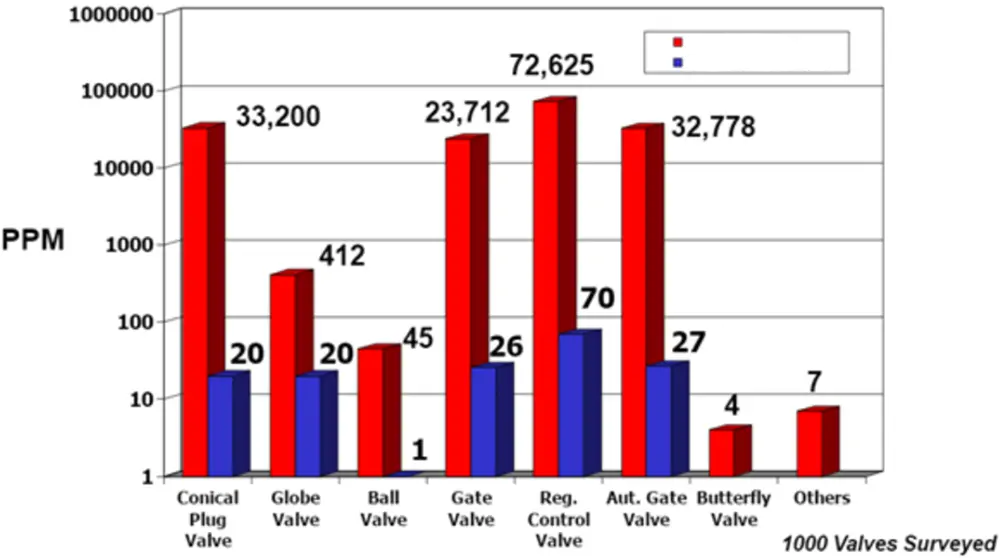

API 624. This covers the testing of rising stem valves using methane as the test media. The valve must perform 310 cycles as well as three thermal cycles (where the valve is tested at ambient temperature, an elevated temperature, then again at ambient temperature) with a leak rate under 100 parts per million (ppm) methane.

API 641. This details the testing of ball valves using methane as the last media. Each valve tested must perform 610 cycles as well as three thermal cycles with a leak rate under 100 ppm methane.

API testing provides a simple pass or fail result. The valve is either certified as a low-E valve or not.ISO test methodology allows for various "class" ratings of valves related to how they perform during testing.

For the full article on FUGITIVE EMISSION CERTIFIED VALVES IN STOCK ISO 15848-1, API 622/624 click here.